Chiyoda Sales Co., Ltd.

Installing carefully-selected devices and equipment

to create better quality and better living

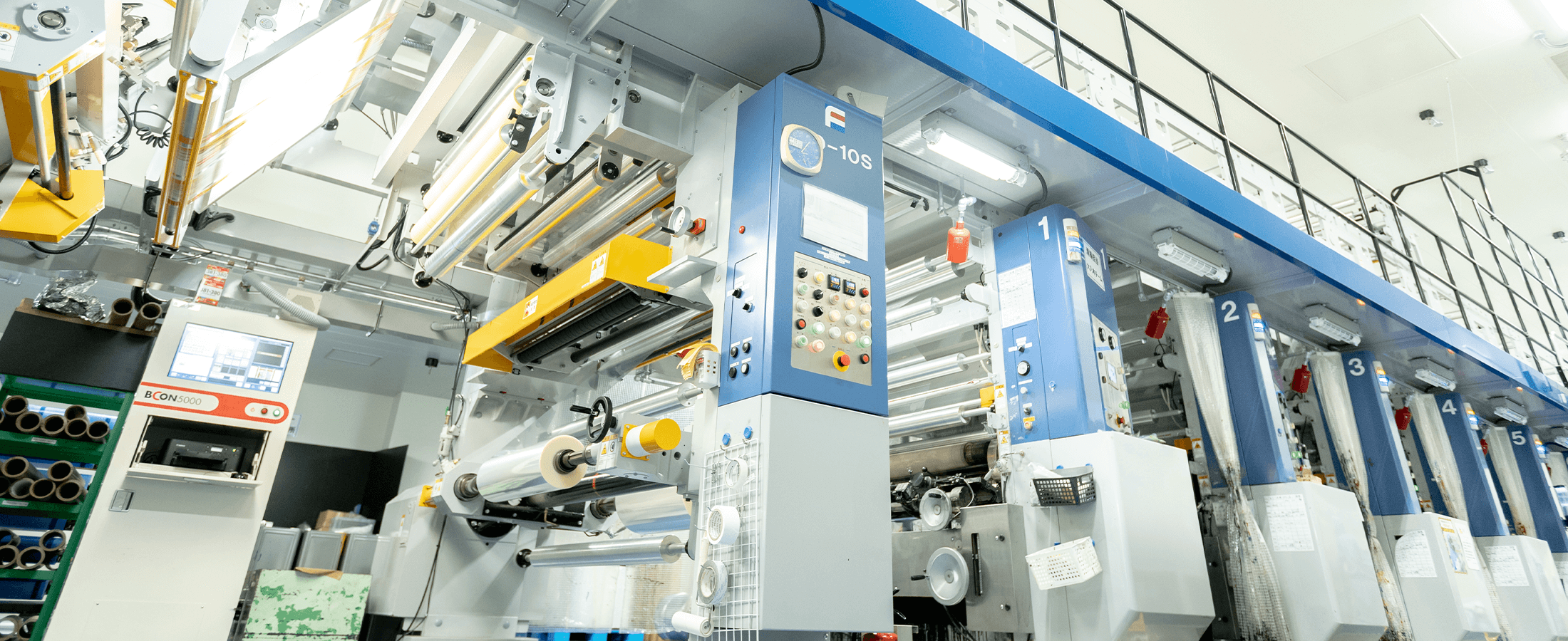

Since its founding in 1957, Chiyoda Sales Co., Ltd. has manufactured and sold plastic film packages. Modifying their production equipment to meet the needs of the era, they have used their reliable processing skills in rotogravure printing, dry laminating, slitting, and bag-making to continue to provide packages that provide safety and peace of mind.

We visited their Kyoto Plant to ask them about why they installed rotogravure printing machines and dry laminators for operating in the plastic film packaging industry, as well as issues moving forward.

Rotogravure printing machine

Dry laminator

K.A

Chiyoda Sales Co., Ltd.

Manufacturing Department Manager

K.H

FUJI KIKAI KOGYO Co., Ltd.

Osaka Business Office Sales Member

INTERVIEW

Contents

Installing rotogravure printing machines to meet diversifying needs including applications and the environment

K.H

Please tell us about why you decided to install our products.

K.A

The dry laminator we installed around 1995 was the first unit. After that, we installed a six-color rotogravure machine in 1998, and replaced the dry laminator in 2008. Regarding our recent expansion, we had some concerns about the doctor section in our printing machine from another company, so we carefully checked the attachment accuracy and instability elements around the doctor.

Then, in 2018, we installed the ten-color rotogravure printing machine, in order to respond to diversifying needs, not only for quality but for the environment and applications as well. Since then, we have operated with three printing machines, enabling production with varied characteristics.

Our company’s corporate philosophy is “providing better quality and creating better living.” We have become able to use our advanced processing skills in rotogravure printing, dry laminating, slitting, and bag-making to deliver with even more stability packages that provide safety and peace of mind.

Amazed by the service team’s swift action! Stabilizing quality and the equipment environment

K.H

In the many years you have used our products, was there any event that left an impression on you in particular? What was it?

K.A

I feel that since we installed products from FUJI KIKAI KOGYO, not only our quality but even our equipment environment and working environment has become more stable. Most of all, the service team’s swift action is wonderful. Both before and after the installation, they speedily respond to even minor questions and consultations.

K.H

Thank you very much. Chiyoda Sales handles all of the machines well. Periodic maintenance is carried out systemically, letting us make proposals at the optimal time.

Seeking new value for plastic film packages together with manufacturers and suppliers

K.H

What kinds of products, specifically, are made using our company’s printing machines?

K.A

Products that use plastic film can be found everywhere in your daily life. For example, the packaging film for food products. From rice bags to packaging for sugar, flour, sweets, and more, we perform stable printing for films to meet the characteristics of the contents, including moisture prevention, transparency, strength, and shape.

If the equipment is not operating properly, it can cause delivery delays or faulty products. So, FUJI KIKAI KOGYO’s printing machines fulfill an important role in our stable production.

K.H

Please tell us how you aim to grow in the plastic film industry moving forward.

K.A

In 2018, we expanded our plant wing and installed the ten-color rotogravure printing machine from FUJI KIKAI KOGYO. This enabled us to stabilize our production organization as well as support diverse needs. The equipment expansion used a design that supported environmental actions, the Fire Service Act, and sanitation management. Moving forward, we will continue to reliably carry out everything from packaging planning to design, manufacturing, and delivery as we look to expand the possibilities of developing products with higher added value as well as environmentally-friendly technology together with manufacturers and suppliers, thus pursuing a new future for plastic film.