JAPAN × FUJI BRAND

Using strict pre-shipping inspections

to achieve reduced trouble and speedy start-ups

Major parts are produced at our Head Office Plant, and other parts are consistently procured from within Japan.

After passing through strict quality management using 3D coordinate measuring machines and the like, products are assembled once at the Head Office Plant, where dedicated technicians repeatedly carry out adjustments and tests until the products meet customer needs, and then the products are shipped.

By performing strict pre-shipping inspections, we eliminate trouble during on-site installation, and also achieve start-up speed overwhelmingly faster than our competitors.

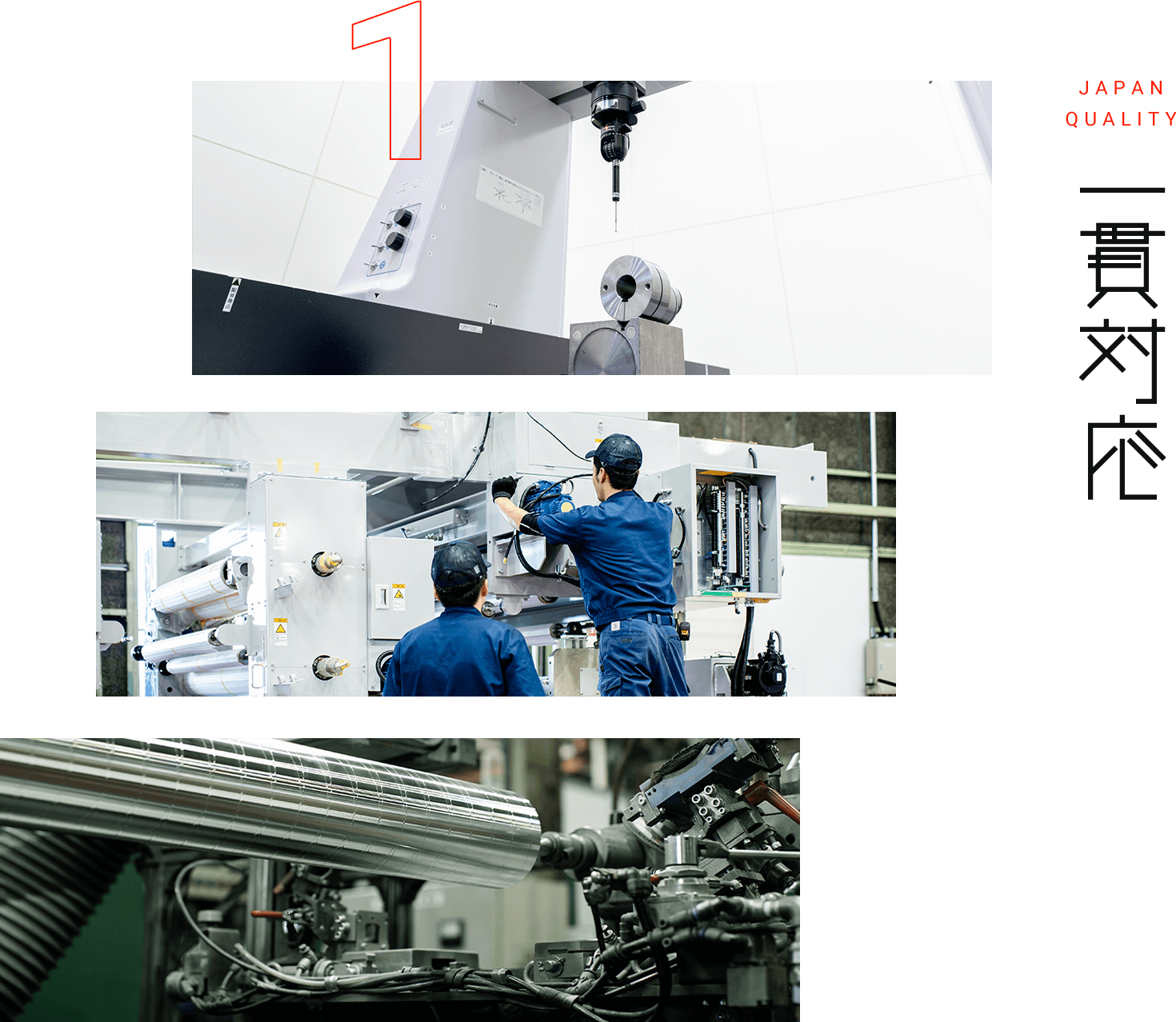

Using the latest machinery and masterful technical skills

to achieve overwhelmingly high printing accuracy

While virtually all printing machine manufacturers outsource the creation of important parts such as the cylinder, cylinder housing, frame, and base in metal printing machine manufacturing, we perform detailed processing using in-house equipment and strict tolerance management to maintain high manufacturing quality.

Particularly for the cylinder, the heart of a printing machine, master mechanics perform processing using dedicated grinding machines under year-round temperature management in a dedicated grinding room located in our own Plant, thus achieving overwhelmingly high printing accuracy unavailable anywhere else.

In the same way, guide rolls, an important part of rotogravure printing machines, are processed using the latest processing machinery in our Plants, with exclusive staff for each process performing confirmation.

With a beautiful machined exterior, an original mechanism that allows for high-speed transport, G1-class dynamic balancing, and the like, we thoroughly ensure a meticulous and optimal finish.

Thoroughly customer-oriented design

based on know-how cultivated since our founding

Based on the know-how we accumulated since our founding in 1951, we use 3D-CAD and simulation analysis with a thorough customer orientation to design one-of-a-kind machines specifically for our customers.

We engage in research and development each day in order to meet the diversifying needs of manufacturers (in terms of speed, accuracy, labor-saving, and the environment).