Test Machine Introduction

We perform various kinds of demonstration tests for coating and lamination.

We also perform tests to meet customer needs. Please feel free to inquire for more information.

We perform various kinds of demonstration tests for coating and lamination.

We also perform tests to meet customer needs. Please feel free to inquire for more information.

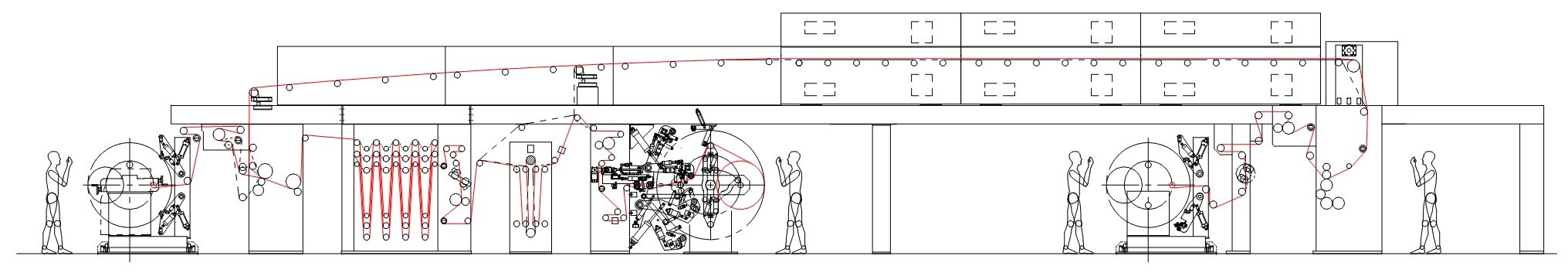

| Coating method | Quadruple squeeze roll method |

|---|

| Material width | 500 to 1,150 mm |

|---|

| Guide roll width | 1,200 mm |

|---|

| Material transport speed | 200 m/min (3-inch core) 300 m/min (6-inch core) |

|---|

| Unwinding device | Bi-axial turret type (maximum web diameter of 600 mm) |

|---|

| Rewinding device | Bi-axial turret type (maximum web diameter of 800 mm) Tapeless method |

|---|

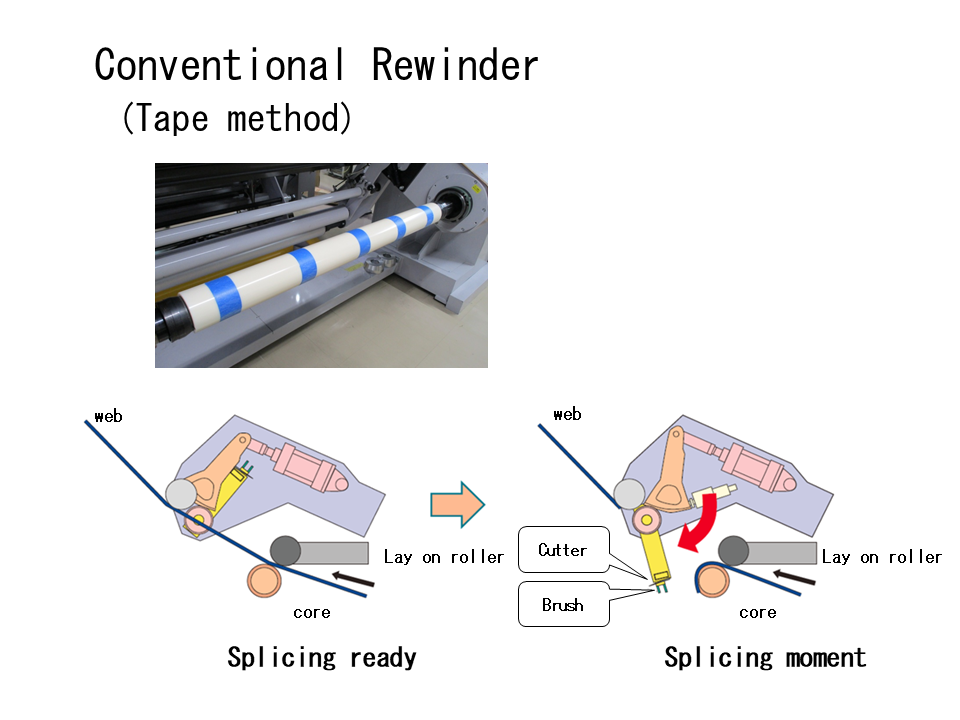

In conventional tape rewinding, during core replacement, adhesive tape is applied to the core as shown in Photo 2 in advance, and then the press roller pushes the web against the core. A bit downstream from there, a cutter blade cuts the web, and simultaneously, the brush brings the cut edge up against the press core, thus beginning a new rewinding process.

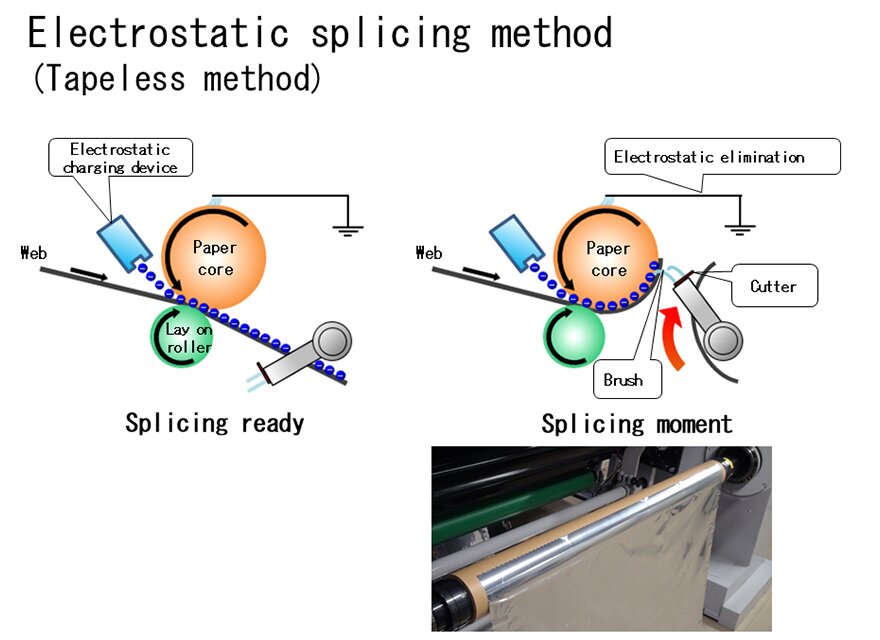

The tapeless rewinding device we developed consists of a web cutter, brush, rewinding core, static electrification device, static eliminator bar, and press roll. First, the rewind turret is readied for splicing. At this time, the static electrification device moves to its set position. When movement is completed, the web and core are electrified for a certain amount of time. After that, the cutter cuts the web and the brush on the rear of the cutter is placed against the core, thus attaching the web to the core. Rewinding to the new core begins. At the same time, the static electricity used to electrify the core is eliminated. This series of operations enables static electrification splicing without using tape.