Product list

Coaters

Coaters use rotogravure coating technology to contribute to industry. Our real technology lies in giving form to our customers’ feelings. We begin from an intangible state and ultimately deliver a machine that makes our customers satisfied. That is our strength.

Equipped with a micro chamber doctor that can coat slurry with a thin film

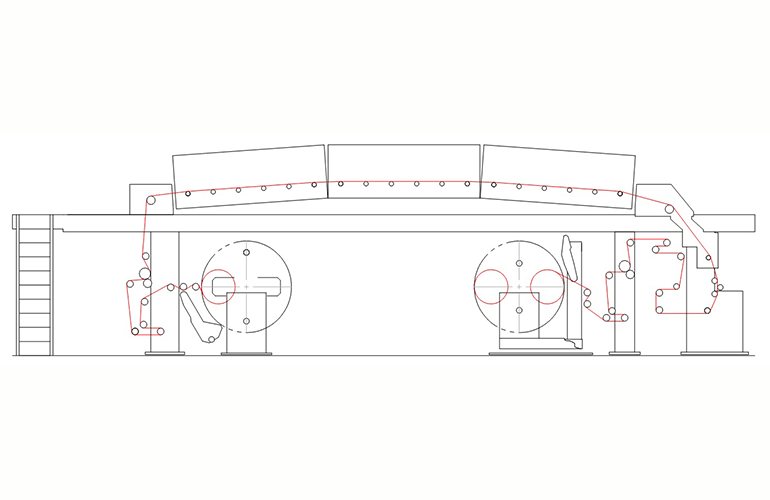

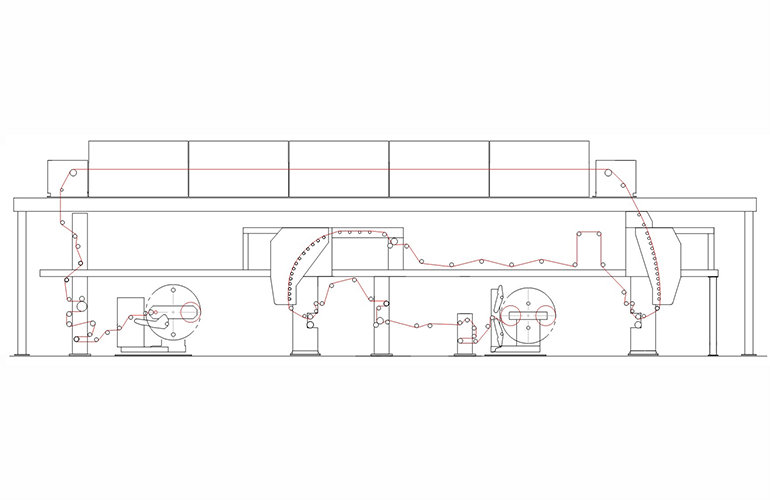

C7-130(Lithium-ion Battery Applications)

Equipment for coating a separator with heat-resistant material such as aluminum oxide. Equipped with a pre-coating seasoning function. It also handles wrinkles of all kinds. Also, a special mechanism in the rewinding section successfully reduces core loss during rewinding automatic splicing.

See details

Equipment developed for thin-film coating and high-speed coating

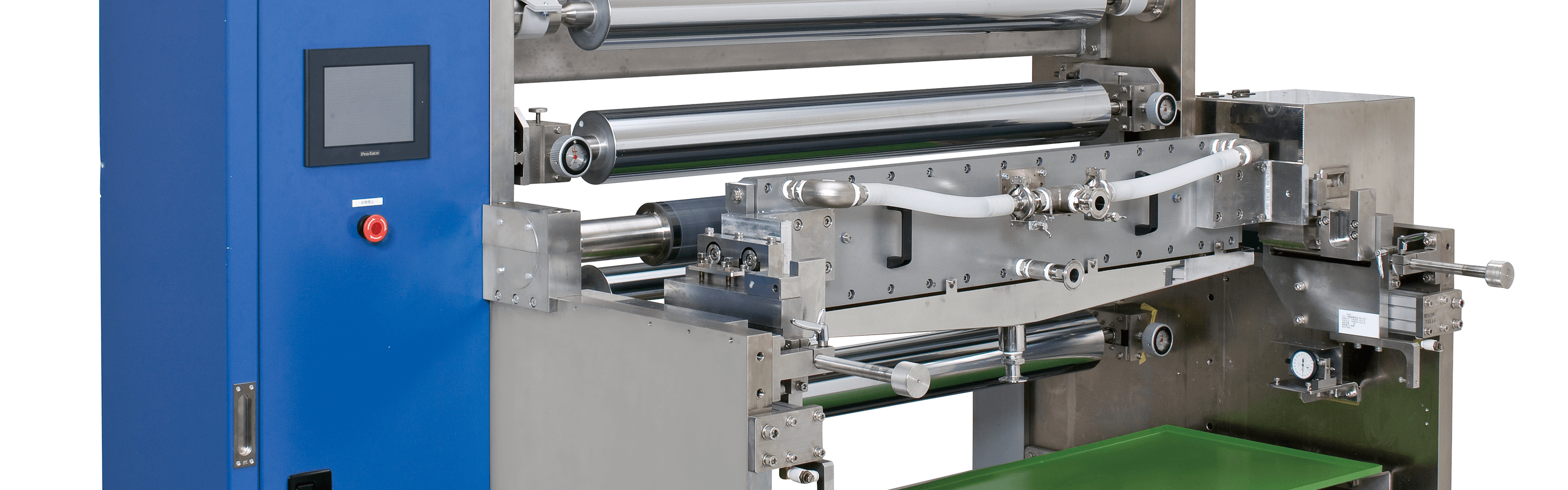

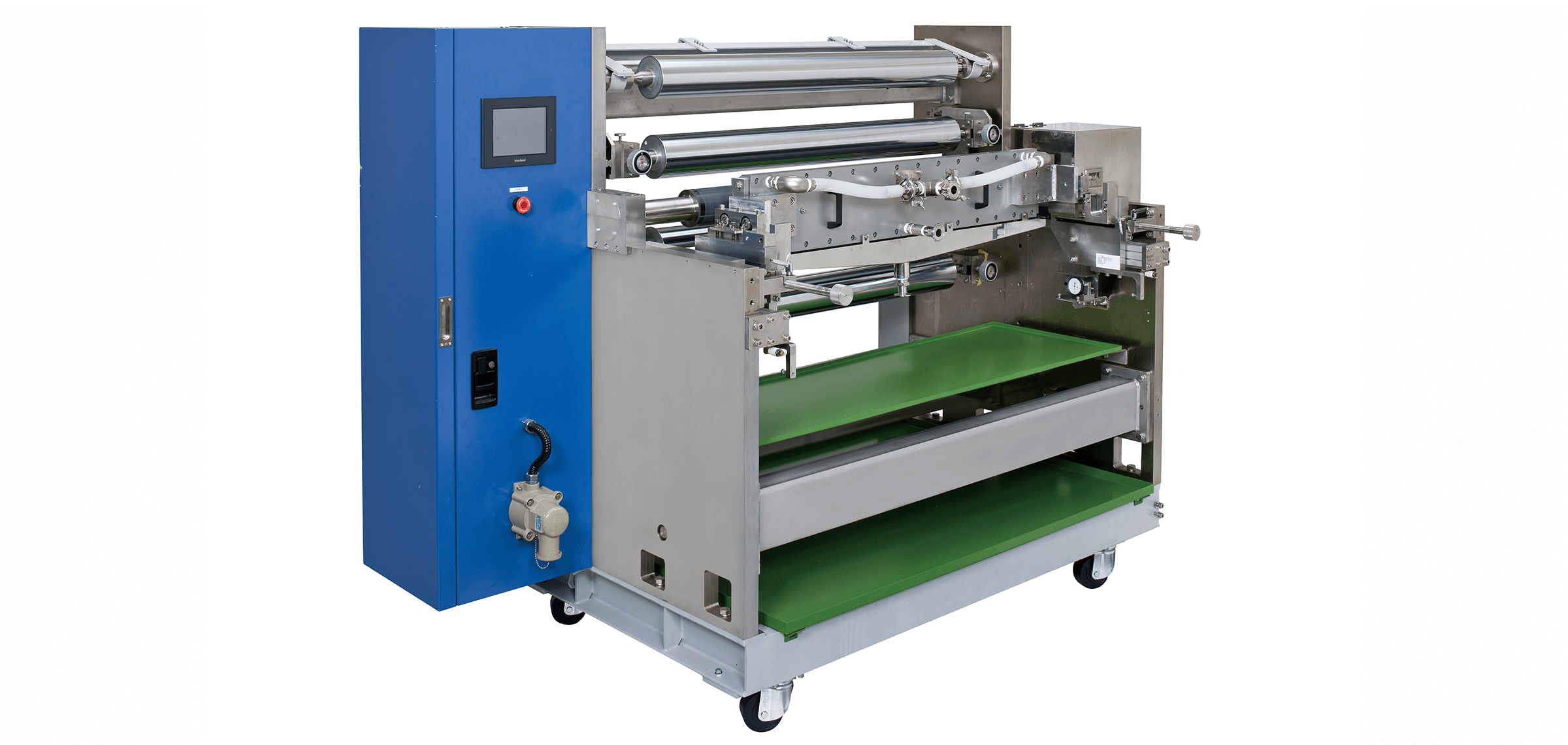

MCD(Micro Chamber Doctor)

We developed a chamber doctor device that performs fluid circulation in a closed system and uses the kiss reverse method to enable thin-film coating as well as high-speed coating.

See details

Equipment that can perform sequential dual-side coating! Equipped with a low-floor type dryer for compact design

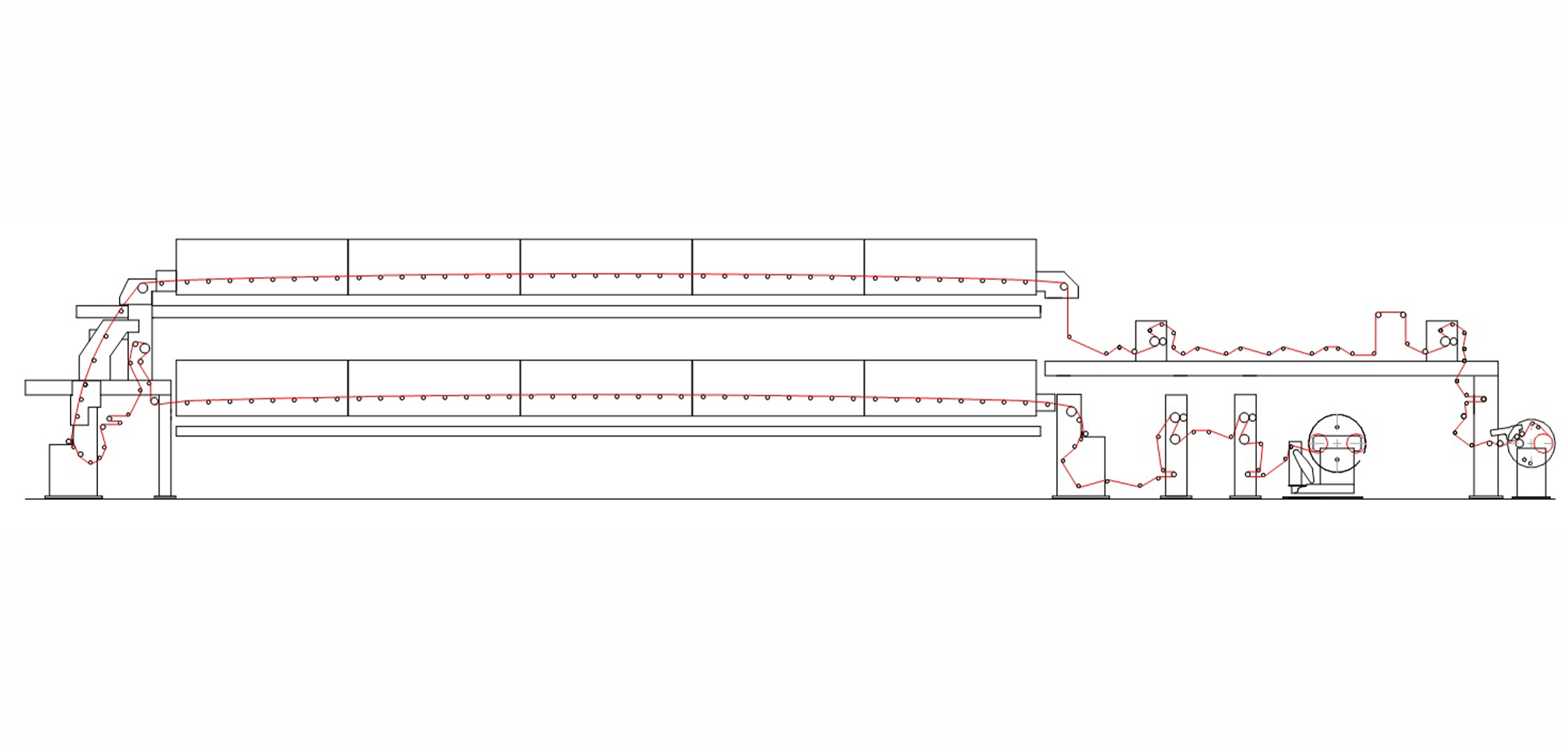

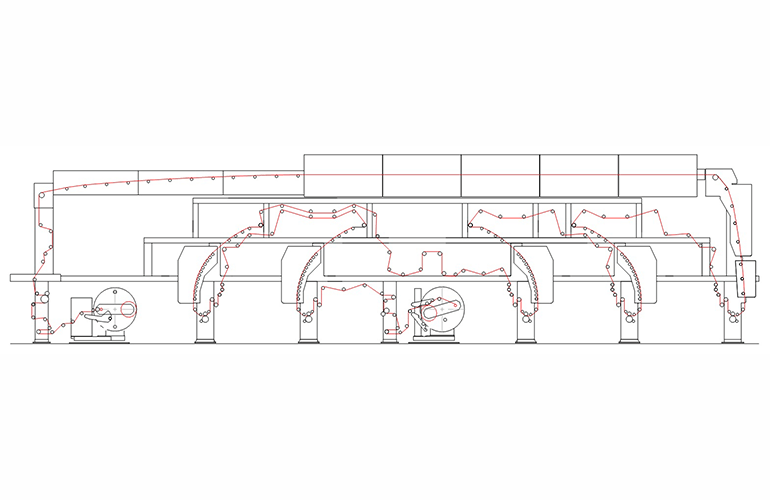

C7-130-2(Lithium-ion Battery Applications)

Equipment for performing dual-side coating on a separator with heat-resistant material such as aluminum oxide. This machine thoroughly pursues improved operation rates and loss reduction.

See details

Here is the sequential dual-side coater. This machine can coat the positive pole with a thin film of conductive material at high speed and successfully reduce loss

C7-085(Lithium-ion Battery Positive Pole Coating Applications)

Equipped with two coating heads and a dryer, this machine supports dual-side coating. The dryer is a low-floor type.

See details

High-performance yet environmentally-friendly! Our latest solventless coating model is even easier to use!

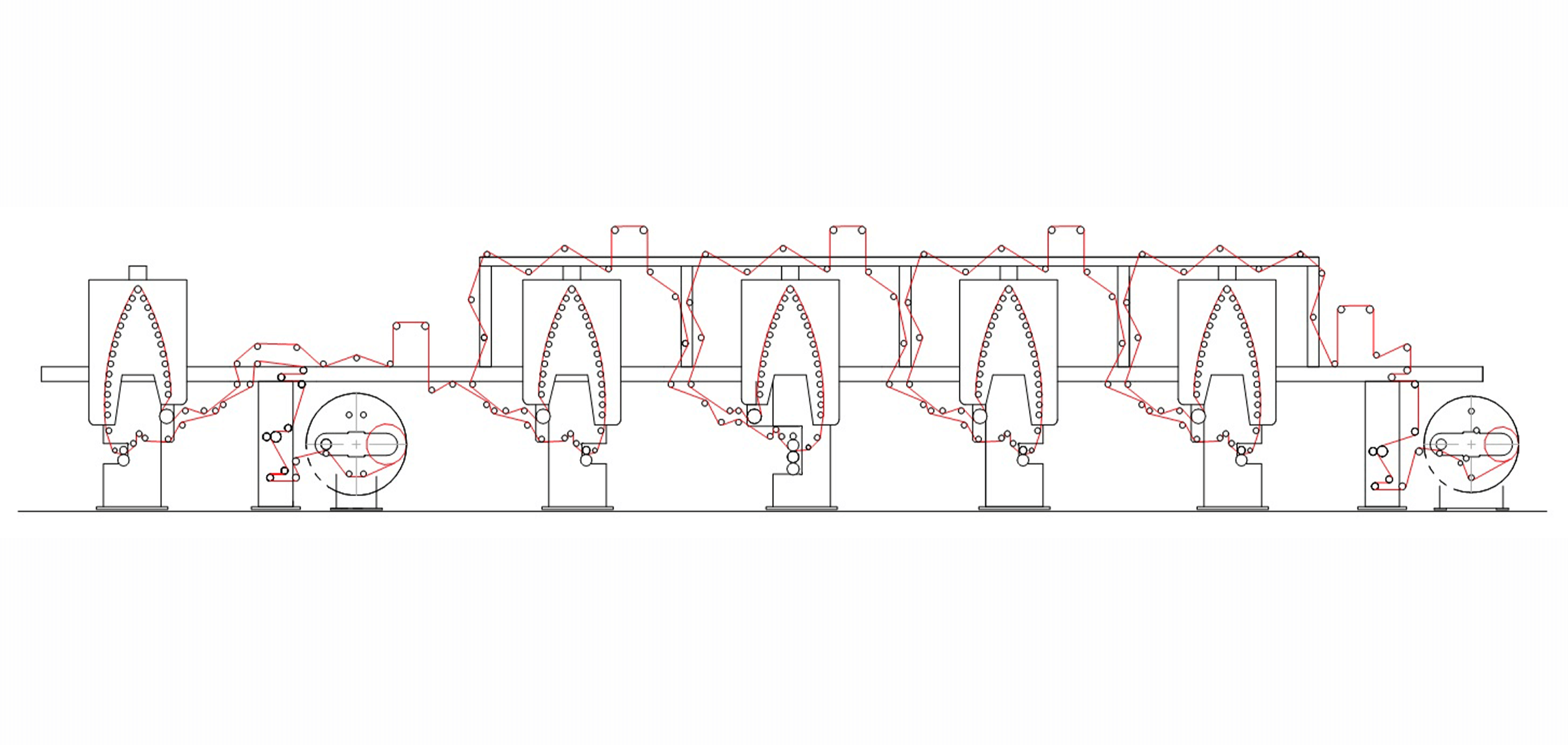

C5-130-2(Lithium-ion Battery Applications)

Achieves desensitizer dual-side thin-film coating for aluminum foil. Operating the rotogravure roll in reverse allows for stable coating and preserves the coating amount. Includes a floating zone and carrier chain mechanism.

See details

Printing cylinders are driven by the sectional method, allowing for easier access to the driving-side space

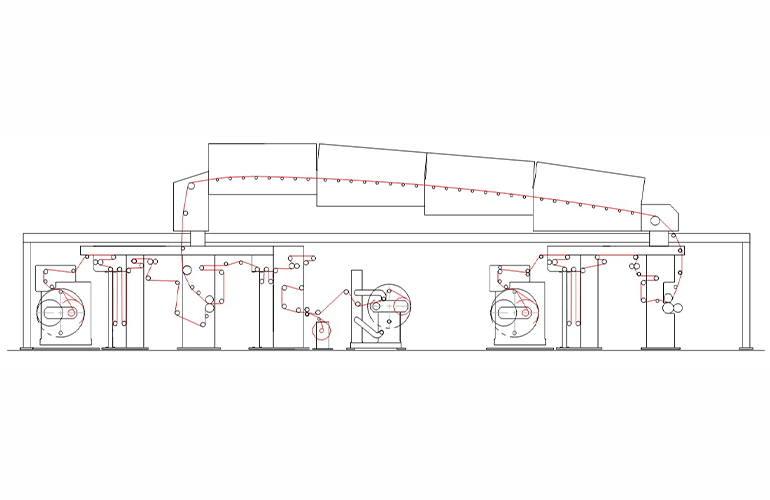

C5-110-5(For Press Through Packs)

Equipped with a carrier chain function that enables foil threading in a short time. Foil threading can also be performed in the printing dryer unit and floating zone. Printing cylinders are driven by the sectional method using AC servo motors, replicating stable register accuracy at the compensator roll.

See details

Also supports thin films! Aggregated technology completed by 2.5 μ transport results

C9-100-5(Ribbon Coater)

Using a Mayer bar with outstanding coating surface properties and substrate transport technology, this machine transports even thin substrates without wrinkles. For a hot melt unit, you can install a heating system for the rotogravure roll and chamber doctor.

See details

For stable application of high-viscosity adhesives

C9-056(For Flexible Substrates)

Equipped with an accumulator to reduce loss when switching between unwinding and rewinding. The coating section is equipped with a triple-roll reverse coater to enable coating with a film thickness of 20 μ to 300 μ. This machine is equipped with an in-line laminator mechanism.

See details

Compact equipment supporting thin-film coating and high-speed operation

C7-060(Lithium-ion Battery Exterior Applications)

This supports stripe coating to match the electrode width. Furthermore, highly-accurate positioning technology for the front and back supports high-speed operation.

See details