Latest world-renowned international model!

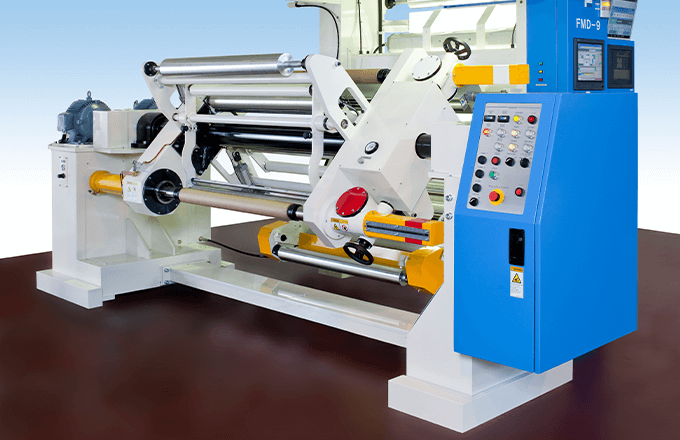

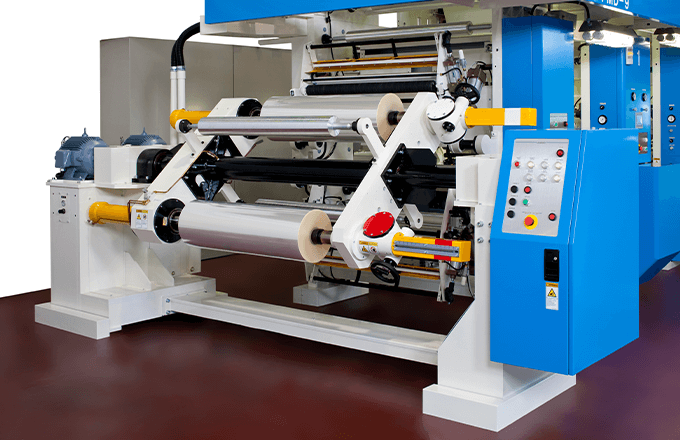

FMD Series(Film Applications)

This model is mainly used for overseas uses. It supports large-diameter material.

Latest world-renowned international model!

FMD Series(Film Applications)

This model is mainly used for overseas uses. It supports large-diameter material.

Features

01

High-quality printing through uncompromising high register accuracy

Each printing cylinder is driven by an AC servo motor to improve synchronization accuracy even higher than the previous compensator roll method.

02

Reducing loss through ever-evolving tension control

Using a combination of speed control and tension control for the infeed tension control method enables more precise tension control. Also, the tension pick control amount is given as feedback to the motor for smooth tension control.

03

Variety of options for customization to meet needs

We can add customization such as turn bars or cooling roll driving to meet customer needs.

04

Emergency response to failures using the remote maintenance function

We can use the remote function to check the current status of your machine, not only within Japan but overseas as well.

05

Repeat function

If you perform initial registering once, this data can be stored in the machine to allow immediate production next time with the same printing conditions.

![]()

Secure and stable development through rich experience and expansive equipment

Ikeda Corporation, Ltd.

See moreImages

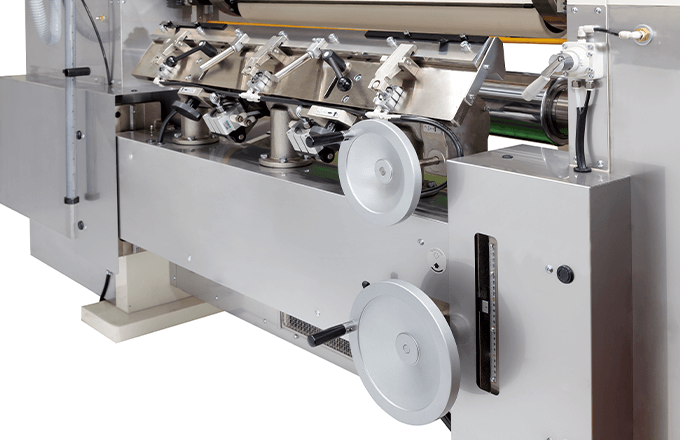

Rewinder unit (Independent type)

Unwinder unit (Independent type)

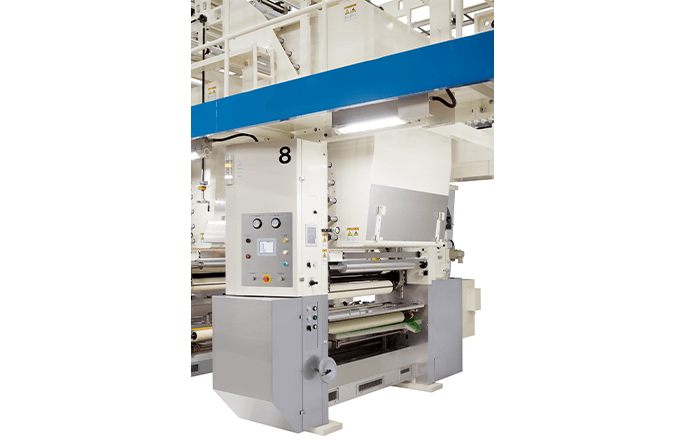

Printing unit

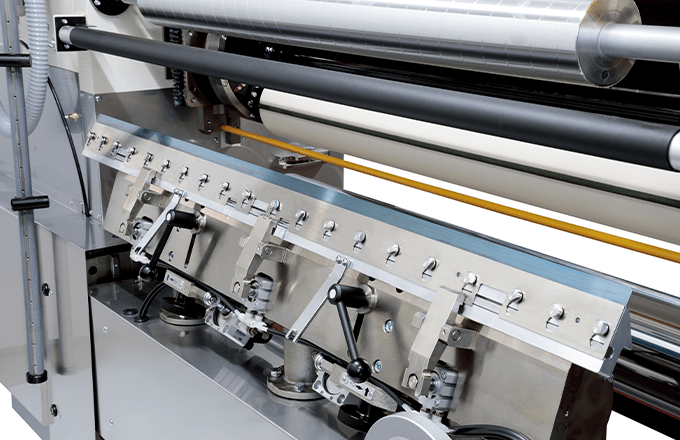

Doctor device

Doctor holder

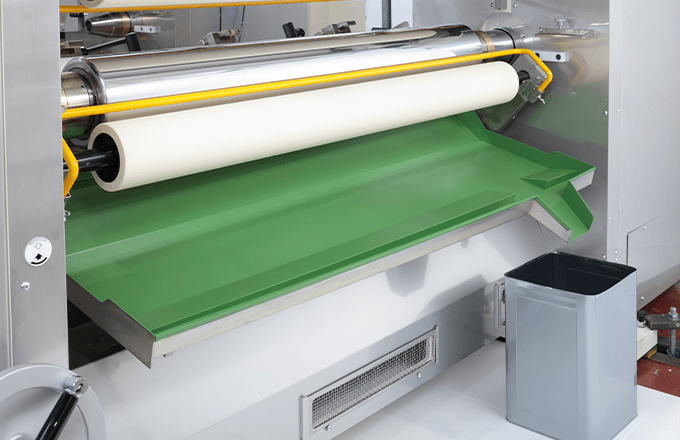

Ink Furnisher roller device and ink pan

Standard specifications